The Vacuum Pressure Tank is an innovative pump system, specially developed for pumping thick, pulpy products for biogas installations.

Feeding to the digesters must not be interrupted due to malfunctions and maintenance, as this almost immediately means a lower biogas production and thus loss of turnover. The ingenious design of the Vacuum Pressure Tank ensures that problems with pumping are a thing of the past.

The seizing of pumps, only being able to pump liquids with relatively little dry matter, having to replace parts frequently: all are a thing of the past with the Vacuum Pressure Tank developed by Biogas Plus.

Because the vacuum pump and the accompanying motor themselves do not come into contact with the biomass, the pump system is hardly susceptible to faults and is virtually maintenance-free.

Depending on the mixture, slurry of 25-30% dry matter can be pumped without any problems. More dry matter usually means more energy and a more efficient fermentation.

Advantages of a Vacuum Pressure Tank are:

- Pumping slurry with high% d.s.

- Very high capacity

- Hardly susceptible to interference

- Virtually maintenance free

- Low energy consumption

- Simple dosing fermenter

- Low pressure in the line

- Long lifespan

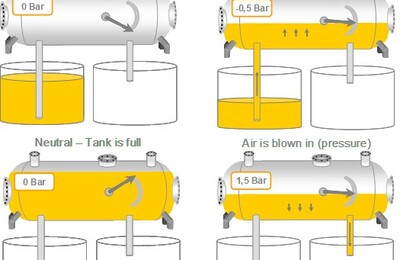

The Vacuum Pressure Tank is evacuated so that the tank fills with biomass. Subsequently, the tank is pressurized and the biomass is pressed to the relevant tank / silo. An additional advantage of the principle of the Vacuum Pressure Tank is that the same pipe is used for the pressing as for the suction. This saves a lot of expensive piping and increases your flexibility.

With the Vacuum Pressure Tank you can also dose much more accurately than with traditional pumps.